Marine batteries and car batteries may seem interchangeable due to their similar appearance, but they serve distinct purposes and operate under different conditions.

While a car battery primarily provides a substantial but short burst of power to start an engine, a marine battery’s role extends further. It not only starts the boat engine but also powers the array of marine accessories over a longer period.

The design and materials used within each type of battery cater to these differing roles, with marine batteries built for deep-cycle use and car batteries made to handle high starting currents.

The environments in which these batteries function also play a critical role in their design. Marine batteries must withstand constant vibrations, frequent tilting, and potentially corrosive marine environments. They are thus designed with heavier plates and vibration-resistant construction.

Car batteries, however, operate within the comparatively stable conditions of a vehicle and are built for quick energy delivery to start the engine.

Understanding the nuances of each battery type helps in making informed decisions for their respective applications, ensuring reliability, longevity, and safety.

Marine Battery vs Car Battery Overview

- Marine batteries are designed for long-term power and durability, while car batteries are optimized for high starting currents.

- The design and maintenance requirements of these batteries vary due to their operational environments and purposes.

- Choosing the right battery requires understanding the distinct performance metrics and design considerations of marine and car batteries.

Design and Composition

In discussing marine versus car batteries, it’s essential to understand that their design and composition are tailored to their specific uses. Let’s explore how the construction materials, chemical composition, and size and weight differ between these two battery types.

Construction and Materials

Marine batteries are specifically built to endure the rigors of marine environments. I find that marine batteries tend to have thicker internal lead plates and a construction that emphasizes vibration resistance and corrosion resistance.

This robustness is crucial because they are often subject to a moist, salty atmosphere that can induce corrosion and constant movement that might damage less sturdy components.

On the other hand, car batteries typically have thinner lead plates and are designed for a higher rate of short bursts of energy necessary for starting engines, for which vibration resistance is still important but not to the same degree as in marine settings.

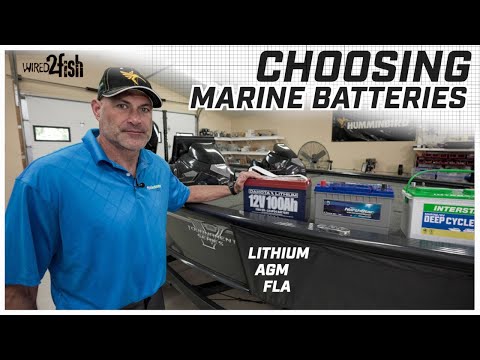

Chemical Composition and Types

The primary types of batteries for both marine and automotive use are lead-acid and more recently, lithium-ion. There are different types of lithium batteries, more notably, LiFePO4 and lithium ion are the 2 most common types.

Lead-acid batteries are divided into starting batteries, deep cycle batteries, and dual-purpose batteries.

Starting batteries are common in cars, providing quick, high-energy outputs to start the engine.

Deep cycle batteries, often found in marine settings, discharge energy more slowly, which suits the prolonged power requirements of marine vessels.

Dual-purpose batteries, meanwhile, can perform both functions to a certain extent. Marine batteries might be of the absorbed glass mat (AGM) type which offer better cycle life and are maintenance-free, a feature appealing for difficult-to-access marine battery compartments. Learn more about AGM vs lithium batteries here.

Size and Weight Considerations

The size and weight of the battery play a crucial role in how it’s designed and where it can be used. Car batteries are generally lighter and smaller because they must fit into a designated space within a vehicle’s engine compartment.

In contrast, marine batteries tend to be larger and heavier, reflecting their larger capacity and emphasis on longevity and sturdiness. The increased weight and size are less of an issue in marine applications where the battery often resides in a lower part of the vessel, aiding in stability.

Performance Metrics

When comparing marine and car batteries, I consider specific metrics to determine their suitability for their respective applications. These metrics include capacity and power output, as well as their cranking amps and discharge/charge cycles, all vital for assessing performance under various conditions.

Capacity and Power Output

Marine batteries often boast a higher capacity than car batteries due to the increased power demands of marine applications. I measure capacity in amp-hours (Ah), indicating the amount of current a battery can provide over time.

Power output, on the other hand, is measured in watts and demonstrates the total electrical power a battery delivers. Car batteries generally prioritize immediate discharge of power to start an engine, while marine batteries offer sustained power over longer periods to accommodate the breadth of marine electronics and deep discharge cycles.

Cold Cranking Amps and Marine Cranking Amps

Cranking amps are crucial to understand; they measure a battery’s ability to start an engine under different conditions. Cold Cranking Amps (CCA) refers to the number of amps a car battery can deliver at 0°F for 30 seconds while maintaining a voltage above 7.2 volts. In my experience, a higher CCA is essential for cold weather starts.

Marine Cranking Amps (MCA), similar to CCA, indicates the ampere output at 32°F and is usually higher than the CCA due to less stringent voltage requirements, reflecting the marine battery’s adaptation to less extreme temperatures but higher moisture environments.

Discharge and Charge Cycles

A primary distinction in performance between marine and car batteries lies in their discharge and charge cycles. Car batteries are designed for shallow discharge cycles with an emphasis on providing a high current for a short amount of time.

Marine batteries, however, are engineered to endure deep discharge cycles, meaning they can be depleted significantly and recharged repeatedly without losing significant capacity.

Charge cycles refer to the number of complete charge and discharge cycles a battery can undergo, with marine batteries typically offering a higher count due to their deep cycle design.

Operational Environments

In discussing operational environments, I’ll outline how marine and automotive batteries meet their unique demands, adapt to temperature and weather challenges, and ensure safety and durability.

Marine vs. Automotive Demands

Marine environments demand more from batteries due to constant exposure to vibrations and moist conditions. Boat batteries must endure these stresses while powering essential electronics and often supporting deep-cycle applications.

Automotive batteries, on the other hand, are optimized for brief, high-energy discharges to start engines, a task measured in Cold Cranking Amps (CCA). They rely on the car’s alternator for continuous power once the vehicle is running.

Temperature and Weather Resilience

Durability in fluctuating temperatures is crucial for both battery types. Automotive batteries, designed for land-based vehicles, confront extreme temperatures and must start engines in cold weather, requiring high CCA.

Marine batteries operational in marine environments must resist corrosion and perform reliably despite temperature swings and exposure to water.

Safety and Durability in Use

For both marine and automotive uses, safety is paramount. Marine batteries often feature additional protection against leaks and spills, given the greater motion and tilt of boats.

They also tend to have thicker internal plates to resist vibrations and safeguard against short-circuits, which are less of a concern for automotive batteries, where their housing and placement minimize movement.

Electrical and Charging Systems

In marine and automotive applications, the electrical and charging systems ensure that the battery functions optimally by regulating the energy input and maintaining battery health. Here, I’ll discuss how these systems differ between marine and car batteries.

Charging System Compatibility

Marine batteries often have unique charging requirements due to the depth of discharge they regularly encounter.

The charging system must be designed to accommodate these needs, ensuring battery longevity. An onboard charger specifically made for marine batteries can correctly match the charging profile, providing the necessary amps without overcharging.

Alternators and Voltage Regulation

Alternators in cars and boats serve similar functions but are constructed differently due to the varying environments. My marine alternator is less likely to be harmed by water and corrosion and is built to handle a deeper depth of discharge.

In terms of voltage regulation, marine systems usually have a sturdy voltage regulator that’s able to handle the power demands of additional marine electronic systems.

Trickle Chargers and Maintenance Charging

For both marine and car batteries, maintenance needs are crucial for preserving battery life. I use a trickle charger for my marine battery to keep it at full capacity during off-season storage, which is essential to prevent the loss of reserve capacity (RC).

This method of maintenance charging ensures that I won’t be met with a dead battery when it’s time to use it, due to self-discharge which happens if a battery is left unused for extended periods.

Service Life and Maintenance

In discussing service life and maintenance of marine and car batteries, I focus on the care they require, expected lifespan, and methods for determining their health.

Maintenance Requirements

I understand that maintenance needs vary between marine and car batteries. For marine batteries, regular checks on electrolyte levels are crucial, as they can deplete during use.

It’s imperative that I keep the battery terminals clean to prevent corrosion and ensure proper electricity flow. I always follow the manufacturer’s maintenance schedule:

- Check electrolyte levels monthly

- Clean terminals quarterly

- Test battery charge bi-annually

Lifespan and Warranty

The lifespan of a battery depends not only on its quality and maintenance, but also on environmental factors. Marine batteries typically endure more demanding conditions than car batteries.

Lithium batteries have a much longer lifespan compared to lead acide ones. For example, here are the best lithium marine batteries that will last about a decade for your boat.

When I buy a battery, I check the warranty closely since it reflects the manufacturer’s confidence in the product’s lifespan. A warranty often ranges from one to several years and includes:

- Limited replacement period

- Prorated warranty period

Determining Battery Health

To gauge a battery’s health, I always measure its capacity to hold a charge over time. A battery tester can be used to check the voltage and assess whether the battery can still perform its intended function.

If a marine battery can no longer keep up with the electricity demands of my boat’s accessories, or if my car battery starts having trouble turning the engine over, it’s time to consider replacement. Here are my steps for health checks:

- Test voltage under load

- Examine electricity output consistency

- Look for visual signs of wear or damage

Choosing the Right Battery

When I select a battery for a specific application, my focus is on meeting the power requirements efficiently and reliably.

Understanding Specific Power Needs

The first step in choosing the right battery is to assess the power demands of the electronics, such as lights, gauges, and pumps. For electric vehicles and golf carts, the focus is on consistent power delivery over time, whereas for starting an engine in a car or boat, a burst of power is essential.

Comparing Starting vs. Deep Cycle Power

Starting batteries are designed to deliver a high surge of power briefly, ideal for igniting an engine.

On the other hand, deep cycle batteries are tailored for prolonged power delivery, suitable for powering electronics consistently.

- Starting Battery: High initial power, low cycle endurance

- Deep Cycle Battery: Lower initial power, high cycle endurance

Selection Criteria for Dual-Purpose Options

Dual-purpose batteries offer a compromise, capable of starting engines and providing continuous power. For an RV battery that needs to support both ignition and continuous use of appliances, a dual-purpose option is preferred.

- Dual-Purpose Batteries:

- Starting ability

- Deep cycle endurance

- Ideal for boats, RVs and versatile applications

By understanding these aspects, I ensure the selection of the most appropriate battery for my needs, whether it’s for a boat, vehicle, or recreational vehicle.

Additional Considerations

In examining marine and car batteries, it is essential to emphasize their distinct physical attributes, ratings, and connectivity options that cater to their specialized uses.

Physical Attributes and Appearance

Marine batteries often present a more robust construction compared to car batteries. Typically, they have thicker internal lead plates, allowing for a more sustained energy discharge suitable for marine environments that demand deep cycle power.

These batteries are designed to handle frequent and deep discharges followed by recharging. In terms of appearance, marine batteries usually feature larger housings with added plastic protection to safeguard against harsh marine conditions, which might include exposure to water and higher levels of vibration.

Connectivity and Terminals

Connectivity is fundamental in both marine and car batteries, but the specifics of their terminals differ. Car batteries typically have top-post terminals, which are easy to connect with standard automotive cables.

On the other hand, marine batteries may come with threaded terminals that provide a more secure connection to withstand the constant motion and potential corrosive environment. This ensures a reliable link to the vessel’s electrical system and helps prevent accidental disconnection due to movement or vibration.

Marine and car batteries are crafted with distinct design principles in mind, necessitating careful consideration when choosing the appropriate battery for specific applications.

FAQ

Is it possible to use a marine battery for automotive applications, such as in a truck or car?

Yes, it is technically possible to use a marine battery in a truck or car. However, I wouldn’t recommend it.

Marine batteries are often heavier and may have different terminal designs than automotive batteries, which can affect installation and compatibility.

If one opts to use a marine battery for an automotive application, they should ensure that the battery fits securely and that the vehicle’s charging system is compatible with the marine battery’s specifications.

Can I use a car battery on my boat?

This is technically possible, however, a car battery will not last very long in a marine environment. In fact, car batteries are not designed to withstand the level of vibrations you have on a boat.

Additionally, car batteries are designed to mostly deliver a quick burst of power, while in a marine application you will likely use the battery also to power the other devices you have onboard. So you will need a deep cycle battery.

What advantages do marine batteries offer over traditional car batteries?

Marine batteries offer several advantages over traditional car batteries, including greater resistance to vibration, deep cycle capabilities, and the ability to discharge and recharge many times without significant loss of capacity.

These features make them suitable for marine applications where a stable and durable power source is critical for both starting engines and running on-board electronics for extended periods.

Related Articles: